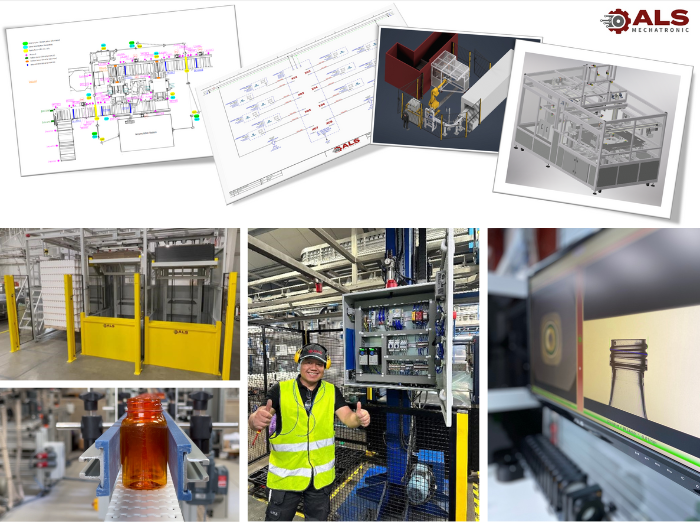

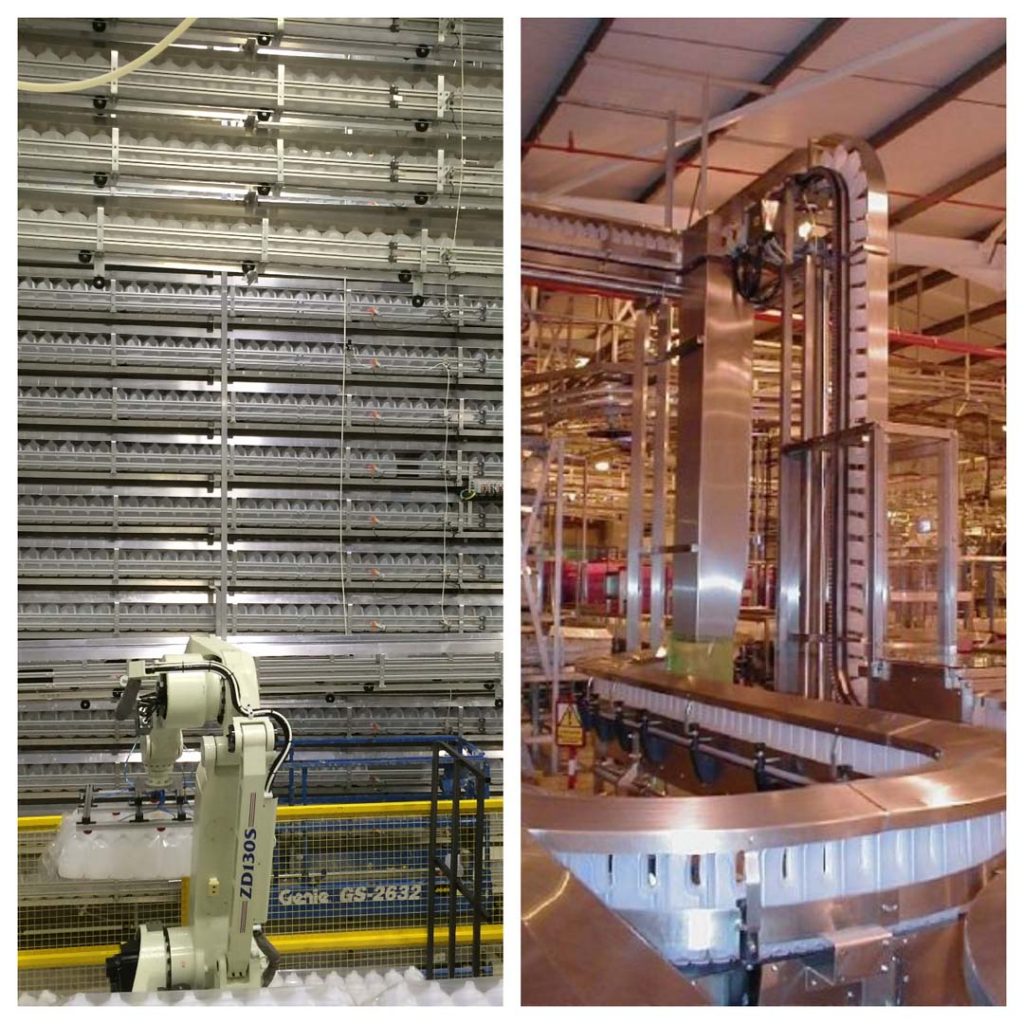

High-speed, end-of-line process and packaging automation is as crucial for container manufacturers as the blow molding process. ALS Mechatronic design, manufacture and install rigid container handling machinery systems suitable in the high-volume production of most HDPE, PET and PP rigid container types including plastic bottles, plastic jugs and vials of any size and style including:

Square and Rectangle Straight-Sided Containers • Round Containers • Water Cooler Bottles • Dairy Gallons • Half Gallons • Litre Milk Jugs • Pint-size Bottles…

…for any liquid: milks, juices, sauces, vinegar, food oils, water, industrial oils, alcohol, soda, medicines, household chemicals and beauty products, as well as pharmaceuticals such as dispensed tablets.

We are the experts in this field, supplying single machine solutions through to full turnkey, multi-site manufacturing automation systems world-wide, comprising:

- Automatic bottle bagging machines (Autobagger)

- Automatic bottle debagging machines (Auto debagger)

- Robotic cells for multi-product picking, placing, sorting, bottle de-flashing

- Conveyors

- Palletizers

- Stackers / Trolley loaders / Pallet wrappers

- (Cardboard) Tray erectors

- Case erectors / Cardboard box erectors

- Case liners / Cardboard box liner machines

- Vision inspection

- Control systems & Control systems retrofit